The iPhone stands as a testament to innovative technology and elegant design, but have you ever paused to consider why Apple predominantly assembles its devices in China? Many might jump to the conclusion that it’s all about cost-effective labor, yet Apple CEO Tim Cook has shed light on a far more intricate reality. During a 2017 interview, Cook provided compelling reasons for China’s ongoing prominence in iPhone assembly—reasons that challenge commonly held beliefs and unveil the intricacies of global manufacturing dynamics.

Debunking the Cheap Labor Myth

When discussions about iPhone production in China arise, the topic often gravitates toward the allure of low labor costs. However, Tim Cook refuted this notion during his 2017 conversation with Fortune. According to him, China is no longer viewed as a haven for cheap labor. Instead, Cook noted that while labor costs have been on the rise, China’s workforce possesses an exceptional level of skills and expertise that many other countries struggle to match.

Cook emphasized that numerous companies, Apple included, turn to China not for low wages but for the availability of a highly skilled workforce. The precision and advanced technologies essential for assembling iPhones are in abundant supply in China. He highlighted the challenge Apple would face in the U.S. to find engineers with the specific expertise needed for their high-tech devices. Conversely, in China, Cook asserts, the company could easily assemble a workforce across several football fields filled with the right talent.

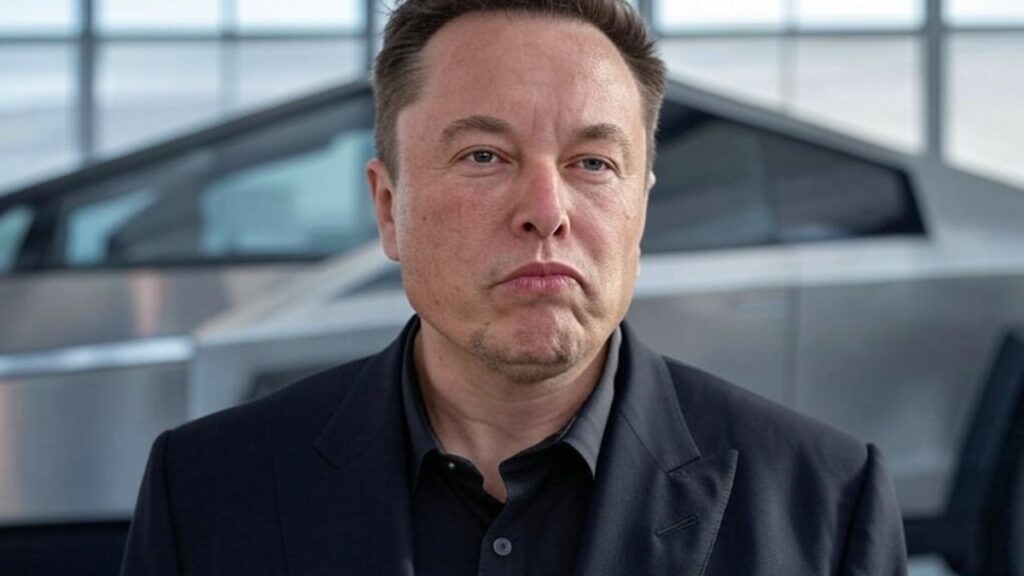

Tim Cook explains why Apple builds in China and why the U.S. isn’t yet ready to take over.

pic.twitter.com/OiEpyIEZlN— Nigel D’Souza (@Nigel__DSouza) April 11, 2025

Apple’s Journey to Diversify Its Supply Chain

It’s pertinent to mention that Apple has actively sought to broaden its supply chain and lessen its reliance on China. Between 2015 and 2017, the company began relocating some manufacturing activities to alternative countries such as India, where a portion of iPhones are now produced. Yet, despite these diversification efforts, China remains a dominant force in Apple’s product assembly. Experts project that around 90% of iPhones are still made in China, underscoring the nation’s critical role in Apple’s operations.

Given the recent trade wars and tariffs thrust upon China by the U.S., Apple has contemplated shifting some production back to American soil. Nevertheless, analyst Dan Ives from Wedbush estimates that merely relocating 10% of Apple’s output from Asia to the U.S. would incur a staggering $30 billion cost and take at least an additional three years to implement. Furthermore, Ives suggests that should the iPhone be fabricated domestically, the cost could balloon immensely—potentially raising a $1,000 iPhone to a jaw-dropping $3,500.

The Real Dilemma: Cost versus Quality

The crux of the matter transcends simple cost considerations; it also involves maintaining the quality that Apple demands. China offers not just a talented workforce but also a robust infrastructure, allowing Apple to uphold the consistency and precision necessary to manufacture millions of devices annually. Even as labor costs continue to rise, China remains the optimal location to ensure that Apple’s assembly operations flow seamlessly.

At the same time, Apple’s ambition to diversify its supply chain and diminish its dependence on China highlights the intricacies of contemporary global manufacturing. While China presents cost-effective solutions and a rich talent pool, it’s evident that trade policies and tariffs could compel companies like Apple to reevaluate their long-term approaches. In this constantly shifting environment, the decision of where to assemble products is influenced by much more than just labor costs.

Conclusion: The Unyielding Dominance of China in iPhone Assembly

While the conversation surrounding manufacturing in China is indeed multifaceted, one fact stands out: China continues to be pivotal in the production of the iPhone. Tim Cook’s insights illustrate that it’s far more than merely about cheap labor; it’s the combination of skills, expertise, and a robust supply chain that enables Apple to uphold its high standards. As Apple navigates its path toward a more diversified manufacturing strategy, it’s evident that China will remain a cornerstone of the company’s operations for the foreseeable future.